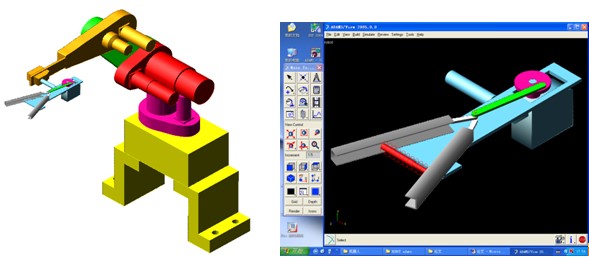

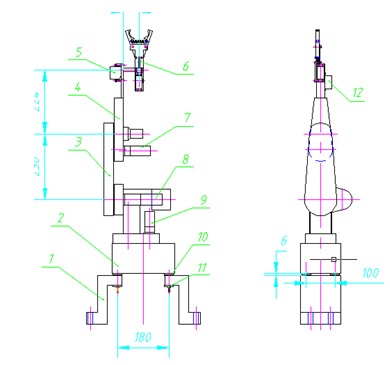

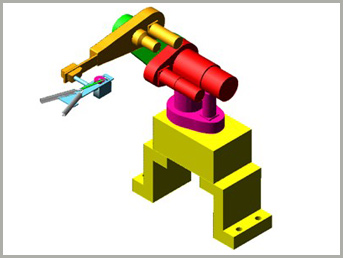

Function: to transport materials for stamping equipment

In contemporary large-scale manufacturing, enterprises, most often than not, attach great importance to the degree of automation in the process of manufacturing, in order to improve productivity and ensure product quality. As a significant part of the assembly line, industrial robots have gradually obtained recognition and adoption from enterprises. To some extent, the technology and application of industrial robots reflect the level of automation of a country. Currently, industrial robots mainly undertake repetitive and labor-intensive work, such as welding, spraying, transportation and stacking in a manner of reproduction of teaching. This project aims to design a four DOF industrial robot to be used to transport materials for stamping equipment. It will design the control system, including the selection of data collection card and servo amplifier, the selection of feedback mode and feedback elements, the design of terminal board circuit and the design of control software. The project focuses on improving the reliability of control system and the safety during the operation of the robots. It ultimately aims to resolve following problems, including the servo and brake of joints, real-time monitoring of all the joints of a robot, teaching and online modification programming of robots and the set-up of reference point and returning of the reference point.